Portable Sawmill Basics: Selection, Setup, and Maintenance

Introduction and Outline: Turning Logs into Value

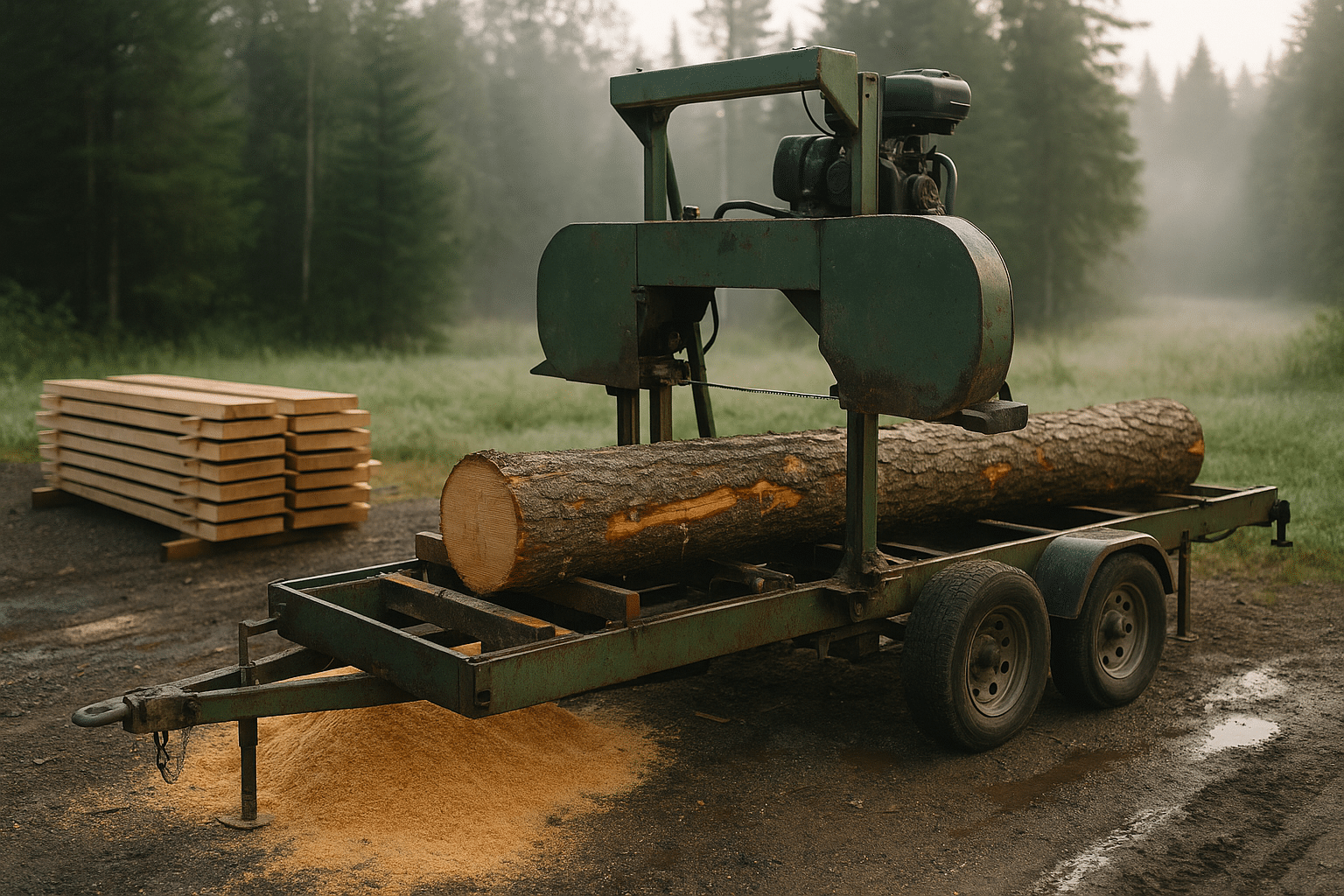

Few tools change how you see a tree like a portable sawmill. Suddenly a wind-thrown oak is not yard waste but flooring; a pine with storm damage is siding rather than firewood. Portable mills let landowners, woodworkers, and small operators convert local logs into boards on their own timeline. The appeal is practical—control over dimensions, species, and drying schedule—but also deeply satisfying. This article lays out a realistic path: how to choose a mill, set up a safe and efficient site, run a productive workflow, and keep the machine cutting true for years.

Here is a brief roadmap before we dive deep:

– Selection: match mill type to log size, portability needs, power, and budget.

– Setup: stabilize the machine, plan log handling, manage sawdust, and protect the work area.

– Operation: choose blades, plan cuts for yield, avoid waste, and stack lumber for drying.

– Maintenance: daily checks, alignment, blade care, troubleshooting, and storage.

Portable sawmills vary from ultralight rigs to trailer-mounted machines with hydraulic log handling. Each choice carries trade-offs in throughput, kerf (the width of cut), fuel use, and accuracy. A typical narrow-kerf bandsaw mill removes roughly 1.5–2.5 mm of wood per pass, while circular mills may remove 4–6 mm; over hundreds of cuts, that difference turns into a measurable jump in board footage recovered. Likewise, a manual mill might average 100–300 board feet per hour in mixed logs, whereas a well-practiced operator with hydraulic assists can see 300–700 board feet per hour under favorable conditions. Numbers vary with species, knot content, log diameter, weather, and blade sharpness, but seeing the ranges helps you plan honestly.

We’ll keep the tone practical and grounded in field habits that work. Expect specific suggestions you can copy tomorrow:

– Small footprint leveling tricks using cribbing and spirit levels.

– Productive cut sequences for common cants and dimensional lumber.

– Blade selection rules of thumb for hardwoods versus softwoods.

– A maintenance rhythm that prevents wavy cuts and premature wear.

Whether you are milling barn siding for a homestead or producing custom slabs for clients, the path is similar: select wisely, set up carefully, operate deliberately, and maintain consistently. Let’s begin with the selection choices that shape everything that follows.

Selecting the Right Portable Sawmill

Choosing a mill starts with the wood you intend to cut and where you intend to cut it. The first filter is log diameter and length. Entry-level band mills commonly accept logs in the 24–30 inch diameter range and lengths of 10–16 feet with bed extensions available. Swing-blade mills can handle larger diameters in the field because the head circles the log rather than pulling the log through a throat, making them attractive when big trees and dimensional timber are the priority. Chainsaw mills shine for ultra-portable, low-cost slab work, but their kerf is wider and productivity is lower, so they are a niche option for occasional, remote cuts.

Power and portability come next. Small gasoline engines (often in the 9–25 horsepower range) are common and easy to service. Electric options require reliable power but can run clean and quiet. Trailer-mounted frames simplify transport and set-up time; bolt-together ground frames cut initial costs but take more site work. Consider how often you’ll move the mill and how rough the access roads are. If you plan frequent moves between jobs, a balanced trailer package with adjustable outriggers saves hours of leveling effort in the long run.

Throughput and labor are intertwined. Manual mills ask more of the operator: rolling heavy logs with cant hooks, clamping cants, and dogging boards by hand. Hydraulic assists—log loaders, turners, toe boards, and powered clamps—reduce fatigue and increase consistency, especially on mixed-diameter logs. If you mill more than a day or two each month, hydraulics tend to pay back in less strain and better daily output. Accuracy features also matter: adjustable blade guides, consistent tensioning, and fine lead adjustment help prevent washboarding and taper in boards.

Budget should be weighed against total ownership costs rather than sticker price alone. Look at:

– Blade costs per board foot and the availability of sharpening and setting services.

– Fuel consumption per hour and noise limits in your area.

– Upgrade paths such as bed extensions, debarkers, or lube systems.

– Resale value for the configuration you are considering.

Safety and support round out the decision. Verify that the frame is rigid, the guards are robust, and the controls are placed away from pinch points. Check that the manual is thorough and that parts are readily available. A well-regarded design with clear documentation reduces downtime, especially when you need to diagnose cut quality on a deadline. In short, match capacity and features to your most common logs, and leave headroom for the day a neighbor calls with a bigger-than-usual cedar or maple.

Site Setup, Leveling, and Safety Planning

The right site prevents problems that no amount of blade tension can solve. Begin with a stable, drained pad. Packed gravel over a geotextile base resists frost heaving, stands up to rolling logs, and sheds water. If the mill is trailer-mounted, park on the flattest section and deploy outriggers on solid cribbing. A practical guideline is to level within 1–2 mm per meter along the bed; use a long spirit level or a laser to avoid twist that will introduce taper. For ground frames, sleepers made from treated timbers or concrete blocks at regular intervals keep rails true under load.

Plan your material flow as if it were a small production line. Stage logs on the “dirty side,” ideally on bunks to keep them out of mud and grit. Place the mill so you are not dragging bark and soil across the feed path. Keep a clear “clean side” for fresh boards and slabs, and set up a stacking area within easy reach. Sawdust accumulates quickly; a chute and rakes keep it away from belts and bearings, and a tarp or bin helps you reclaim it for animal bedding or compost carbon. Think about weather: shade reduces blade pitch buildup in hot sun, and wind direction matters when sawdust is airborne.

Access and safety go together. Ensure equipment can reach the pad—farm tractors, compact loaders, or log arches make moving logs safer. Create clear walking lanes with traction underfoot. Keep pry bars, cant hooks, wedges, and chocks within arm’s reach but out of trip paths. Establish a routine before you start the engine:

– Inspect blade sharpness and set; replace or resharpen before the day runs away from you.

– Confirm blade tension, guide spacing, and lube flow.

– Check all fasteners on the head, rails, and bed stops; vibration loosens what you ignore.

– Verify guards and emergency stop function.

Noise and dust considerations may trigger local rules, especially near residences. Run during daylight hours, notify neighbors when milling, and keep a spill kit for fuel. Personal protective equipment is non-negotiable: eye protection, hearing protection, gloves with good grip, and steel-toe boots. For log handling, avoid putting hands where gravity wants to put a log; use tools to turn and position. When milling slopes, crib logs to prevent rolling, and never leave a cant perched on toe boards. Slow, predictable movements beat speed every time. A careful setup day often pays back in fewer miscuts, fewer stuck cants, and a calmer operator.

Operation: Workflow, Yield, and Quality Control

An efficient milling day begins before the blade touches wood. Assess each log’s sweep, taper, knots, and heart position, then choose a face that yields the straightest reference. Scale volume to plan your cuts; the International 1/4-inch rule provides a reasonable estimate for many species. With band mills, trim the log ends square and knock off grit with a wire brush—silica dulls teeth fast. Align the pith to minimize growth stress in boards you intend for critical structural work.

Blade choice and feed rate control quality. Coarser tooth pitches suit softwoods and wide cuts; finer pitches and harder alloys excel in dense hardwoods. Keep lube steady—plain water with a dash of biodegradable surfactant can reduce pitch; in freezing weather, a small proportion of eco-friendly antifreeze helps flow without gumming guides. Set blade guides close to the cut to support the band and reduce flutter. If the cut starts to wander, resist the urge to push harder; reduce feed slightly and check tension and sharpness at the next break.

Plan your breakdown sequence for yield. For example, on a straight log:

– Slab the first face to create a flat.

– Roll 180 degrees, slab to parallel the first face.

– Roll 90 degrees, square into a cant sized for your target boards.

– Slice boards from the cant, flipping once to relieve stress and keep thickness consistent.

Kerf matters. Narrow-kerf bands can reclaim 10–20 percent more wood relative to wide-kerf circular blades across many cuts, especially in small-diameter logs. That advantage grows when producing thin stock like 1x boards. Track thickness with calipers and leave a small allowance for planing—commonly 1–2 mm above final dimension depending on species and drying behavior. Sticker stacks promptly with dry, uniform stickers at 16–24 inch spacing, keep stacks shaded and weighted, and aim for airflow on all sides. Good stacking is a hidden form of quality control, preventing warp that no planer can fix later.

Productivity is real but secondary to accuracy and safety. Typical ranges:

– Manual bandsaw rigs: about 100–300 board feet per hour in mixed species.

– Hydraulic-assisted rigs: roughly 300–700 board feet per hour with steady log supply.

– Chainsaw mills: highly variable, often under 150 board feet per hour, optimized for specialty slabs.

Record your cut list, blade hours, and yield. A notebook or simple spreadsheet helps you see patterns: which blades last longer in knotty pine, which species need slower feed, and where setup tweaks save minutes. Over time, your workflow will become almost musical—roll, clamp, cut, stack—with fewer surprises and cleaner boards.

Maintenance, Troubleshooting, and Long-Term Care

Consistent maintenance keeps cuts straight and downtime short. Build a routine around three rhythms. Daily: brush rails clean, check blade tension cold and hot, verify guide alignment, confirm lube flow, and look for pitch buildup on the band and wheels. Wipe sap from belts and guide rollers before it hardens. Weekly: torque-check critical fasteners, inspect bearings for play or heat, examine belts for glazing or cracks, and square the head to the bed. Monthly or every 40–60 hours: check wheel belt crowns, inspect the blade lead, re-level the bed, change engine oil and filters as specified, and review the entire drive system for wear.

Blade care is its own craft. A dull blade will dive in dense grain, washboard in wide cuts, and heat the band until it loses temper. Rotate fresh blades regularly and track sharpenings; many bands accept 4–6 sharpenings before retirement if tooth setting remains consistent. For mixed hardwoods, a slightly lower feed rate with sharp, correctly set teeth often prevents waves better than extra tension. Use a setting gauge and keep left-right set within manufacturer tolerances—unequal set pulls the cut to one side.

When problems appear, diagnose systematically:

– Wavy cuts: check sharpness first, then guide spacing and wheel belt condition; reduce feed and confirm blade tension.

– Blade dives at the end: look for resin buildup heating the band, or insufficient lube; verify log support to prevent closing on the blade.

– Tapered boards: re-level the bed, confirm toe board position, and ensure the head travels without binding.

– Burning or smoke: pitch on teeth, dullness, or too fine a tooth for the species; clean and swap blades.

Environment matters, too. Dust and moisture attack moving parts over time. Keep a cover over the mill when idle, but allow airflow to avoid trapping humidity. In winter, store blades indoors to prevent condensation rust; in summer, shade the lube tank to reduce algae. Grease points on schedule and keep a small parts kit—belts, guides, fasteners, filters—so a minor issue doesn’t end a milling day. Treat rails as precision surfaces: no hammering, no dragging chains across them, and no storing heavy cants on the bed overnight if the site can settle.

Conclusion: From Logs to Lasting Lumber

Portable sawmilling rewards methodical habits. Select a mill that fits your logs and your body, set up a site that flows, cut with a calm rhythm, and maintain with intention. The result is straighter boards, higher recovery, and a safer, less tiring day at the mill. Whether you’re supplying a small shop or building your own projects, the practices above turn local timber into durable value—one clean pass at a time.