Home Heating Systems: Types, Efficiency, and Maintenance Tips

Introduction and Outline: Heating as the Quiet Engine of Home Comfort

When cold weather presses against the windows, a reliable heating system is the quiet engine that keeps life moving. Comfort is the obvious payoff, but the stakes are wider: heating often accounts for a large share of home energy use, commonly ranging from roughly 40% to 60% in colder regions, and it influences health, moisture control, and safety. Choosing a system is not just a hardware decision; it’s also about fuel type, insulation quality, local climate, and long-term maintenance. A poorly matched or poorly maintained setup can mean drafts, high bills, and avoidable repairs, while a well-tuned system delivers steady warmth with surprising efficiency.

To help you navigate the options with clarity, here’s the roadmap for what follows:

– Types of home heating systems and how they work

– Efficiency metrics and how to interpret them across fuels

– Practical maintenance routines that preserve performance and safety

– Upgrade pathways, controls, and building improvements that stretch every unit of heat

– A conclusion tailored to homeowners and renters looking for clear next steps

Throughout this guide, you’ll see balanced comparisons that emphasize fit over hype: a high-efficiency appliance can underperform if ductwork leaks, while a modest system in a well-insulated home can feel outstanding. We’ll connect the dots between technology and building science, showing how air sealing, right-sizing, and smart controls work together. You’ll also find examples that translate abstract ratings into real-world impacts, like how a change in AFUE or COP ripples through seasonal fuel use. The style here is practical and plainspoken, with a touch of storytelling—because understanding heat is easier when the numbers have a narrative. If your goal is dependable warmth at a reasonable cost, you’re in the right place.

Types of Home Heating Systems: How They Work and Where They Shine

Furnaces push heated air through ducts. Gas and oil models burn fuel and vent combustion gases; electric furnaces convert electricity directly into heat. Non-condensing fuel furnaces typically deliver around 80–85% Annual Fuel Utilization Efficiency (AFUE), while high-efficiency condensing models often reach about 90–98% AFUE by extracting more heat from exhaust. Furnaces heat quickly and pair naturally with whole-home filtration, but ducts must be tight and balanced to avoid uneven rooms and wasted energy.

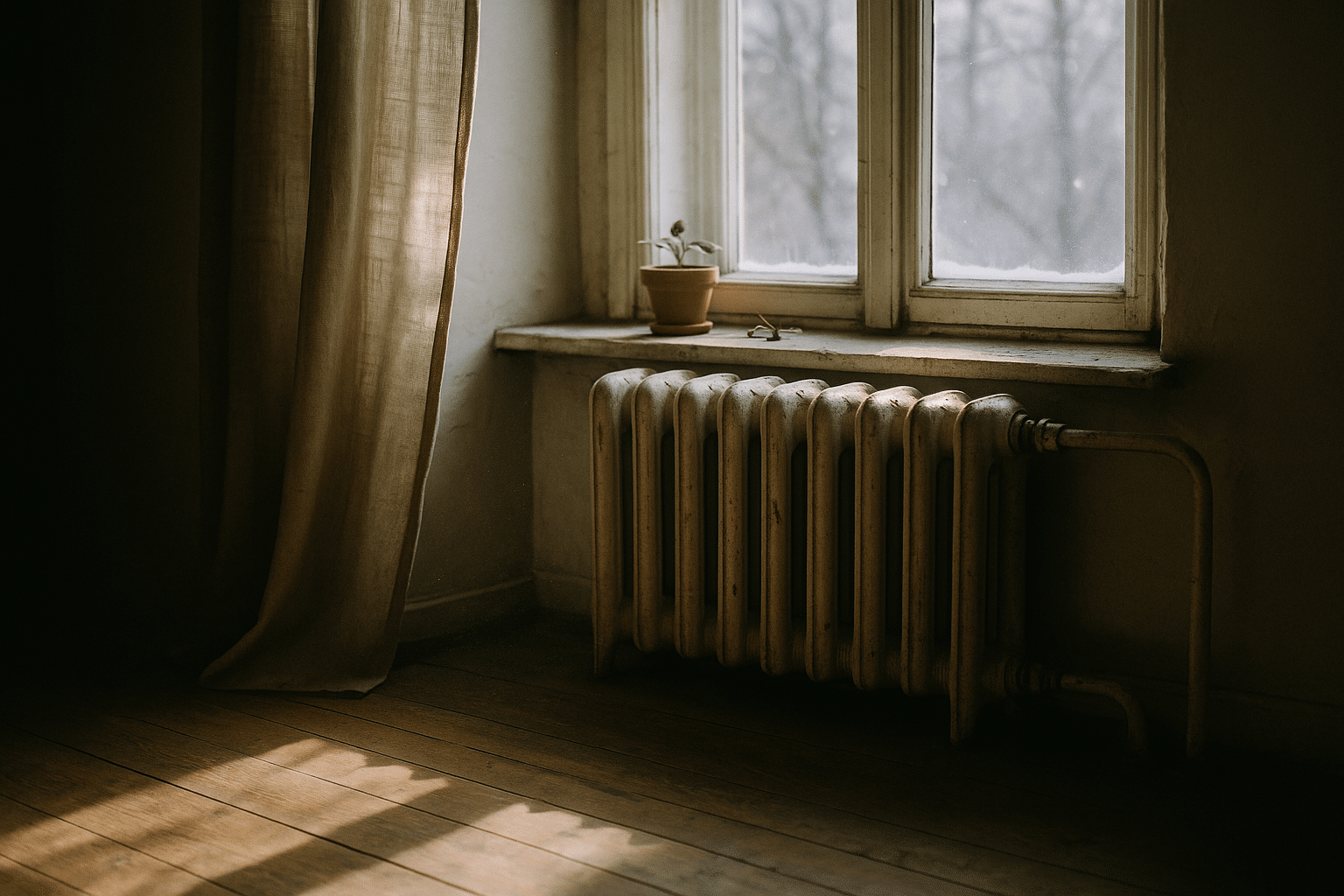

Boilers heat water and move it through radiators or in-floor tubing. Classic cast-iron radiators radiate and convect heat for steady comfort; radiant floors warm surfaces, reducing the chill from tile or concrete. Conventional boilers commonly achieve efficiencies in the 80–85% range, while condensing boilers can reach into the 90s when return water is cool enough to condense flue vapor. Hydronic systems are often praised for smooth, quiet heat, especially in older homes with established piping, though retrofits may be costlier due to plumbing work.

Heat pumps move heat rather than make it. Air-source units pull heat from outdoor air, even in winter; ground-source (geothermal) systems draw from the relatively stable temperature underground. Because they transfer energy, seasonal performance can be strong: air-source models often post Heating Seasonal Performance Factor (HSPF) ratings around 8–12, translating to coefficients of performance (COP) near 2–3 under typical conditions, while ground-source systems can reach COP values higher, often in the 3–5 range in favorable soils. In moderate and cold climates, modern air-source units have improved low-temperature capacity; in the deepest cold, auxiliary heat or a hybrid setup may be appropriate.

Electric resistance heaters—baseboards, radiant panels, or portable units—convert electricity to heat with a COP of about 1. They’re simple and have few moving parts, making them useful for spot-heating or small spaces, but they generally cost more to run than heat pumps where electricity prices are high. Pellet and wood stoves can complement central systems, offering localized warmth and a resilient heat source when fuel supply is secure; typical efficiencies vary widely, and maintenance (ash removal, vent cleaning) matters.

To narrow the choices, consider:

– Furnaces: Wide availability, fast warm-up; watch for duct sealing and filtration upkeep.

– Boilers: Smooth radiant comfort; ensure piping, pump sizing, and water chemistry are right.

– Air-source heat pumps: Efficient in many climates; check low-temperature capacity and defrost strategy.

– Ground-source heat pumps: High efficiency and quiet operation; plan for upfront installation and loop field design.

– Electric resistance: Simple and low maintenance; best for zones or backup where run-time is limited.

No single approach fits every home. The “right” system depends on climate, building envelope, budget, and whether ducts or hydronic lines already exist. In renovations, it sometimes pays to keep existing distribution (ducts or pipes) and upgrade the heat source; in new construction, radiant floors or well-designed heat pumps can unlock excellent comfort with modest operating costs.

Efficiency, Metrics, and Energy Sources: Reading the Numbers That Matter

Efficiency labels are useful, but they tell different stories depending on the technology. AFUE applies to fuel-fired furnaces and boilers and represents the fraction of fuel energy that becomes useful heat over a season. An 80% AFUE unit delivers 80% of the fuel’s energy to the home; the remainder leaves via flue or standby losses. Condensing designs reach into the 90s by cooling exhaust below the dew point and capturing latent heat. For electric-driven systems, two measures stand out: COP describes instantaneous efficiency (useful heat out divided by electrical energy in), and HSPF is a season-averaged rating for air-source heat pumps.

The impact is easier to see with a quick example. Suppose your home needs 50 million BTU of heat through the winter. With an 80% AFUE furnace, that output requires about 62.5 million BTU of fuel input; with a 95% AFUE model, input drops to roughly 52.6 million BTU. That’s a fuel reduction near 16%. For electric systems, a heat pump operating at a COP of 3 uses about one-third the electricity of resistance heat for the same output, a material difference on monthly bills. Real-world results vary with climate, setpoints, duct or piping losses, and how well the system is sized and controlled.

Distribution matters. Duct leaks and poor insulation can waste an estimated 20–30% of heating energy in some homes, and long pipe runs without insulation can sap hydronic performance. Zoning reduces oversupply to little-used rooms, and thermostats with adaptive recovery can avoid unnecessary run-time. Oversized equipment short-cycles, lowering efficiency and comfort; right-sizing against a measured heat load keeps systems in their sweet spot.

Energy sources also shape costs and emissions. Electricity’s carbon footprint depends on the grid mix and time of use; fuels vary by region and price stability. Where electricity is relatively clean and affordable, heat pumps can trim both emissions and operating costs. Where fuel prices are low and winters are severe, a high-efficiency furnace or boiler may be practical, or a dual-fuel strategy can balance performance across temperatures. Building improvements—air sealing, attic insulation, window tune-ups—reduce the load regardless of the heat source, often yielding returns that rival equipment upgrades.

Key numbers to check when comparing options:

– AFUE for furnaces and boilers, noting whether the design is condensing and vented appropriately.

– HSPF and low-temperature capacity for air-source heat pumps; COP estimates for ground-source.

– Duct leakage rates or blower-door test results that indicate how much air escapes the envelope.

– Estimated seasonal heat load, not just square footage, for right-sizing.

– Controls strategy: setbacks, zoning, and supply temperature modulation where applicable.

Maintenance and Troubleshooting: Keeping Heat Reliable and Safe

Even a highly rated system loses its edge without care. Filters in forced-air systems can load up quickly, restricting airflow and forcing longer run-times; swapping or cleaning them every 1–3 months during heavy use helps maintain efficiency and indoor air quality. Dirty filters alone can boost energy use noticeably, and dust on coils undermines heat transfer. Ducts benefit from sealing at joints and insulating in unconditioned spaces to curb losses and condensation risks.

Boilers and hydronic systems ask for a different routine. Bleeding radiators to remove trapped air restores full output; checking system pressure and inspecting for leaks protects pumps and valves. If you have a condensing boiler, keep the condensate drain clear and ensure return water temperatures are low enough to enable condensing when appropriate—this is where outdoor reset controls shine by trimming supply temperatures on milder days. Radiant floors should circulate freely; air bubbles or stuck actuators can turn a cozy slab into a cool one.

Heat pumps reward cleanliness and airflow. Outdoor units need clear space around the coil for breathing room; vegetation, snow buildup, or stacked items can block intake. Gently rinsing fins and ensuring the defrost cycle isn’t fighting ice accumulation protects performance. Indoors, keep returns unobstructed and verify that condensate lines are clear. If you notice frequent cycling, unusual noises, or stubborn cold spots, start with simple checks: clean filters, verify thermostat settings, and confirm registers or radiators are open.

Safety belongs at the center. Fuel-burning appliances should be vented properly, with annual inspection of heat exchangers, flues, and gas or oil connections. Install carbon monoxide detectors on each floor near sleeping areas, and maintain clearances around equipment to prevent overheating. If you detect fuel odors or suspect a venting issue, shut the system down and call a qualified technician. Portable space heaters deserve special caution: give them generous clearance, stable footing, and turn them off when unattended.

A seasonal checklist helps keep things simple:

– Fall: service appointment, filter change, thermostat test, duct and pipe insulation checks.

– Midwinter: visual check of outdoor units, snow clearance, quick filter inspection.

– Spring: final filter change, condensate line flush, note any rooms with chronic comfort issues.

– Anytime: watch energy bills for sudden changes, which often signal developing problems.

A little attention goes a long way. Regular care can prevent breakdowns, keep energy use in line with expectations, and extend service life. When in doubt, document symptoms and call a pro—clear notes shorten diagnostic time and often reduce costs.

Smart Upgrades, Practical Tips, and Conclusion

Before swapping equipment, shrink the load. Air sealing and insulation are the unsung heroes of cozy homes: sealing rim joists, weatherstripping doors, and topping up attic insulation can calm drafts and let systems run at gentler outputs. Window improvements need not be dramatic—caulking gaps, fixing sash locks, and using snug interior shades at night can cut losses. In basements and crawlspaces, targeted insulation against exposed ducts and hydronic lines protects heat you’ve already paid for.

Controls shape comfort and cost. A well-programmed thermostat can trim heating use without sacrificing comfort, especially if it learns your schedule or ramps up heat gradually before you wake. Zoning helps homes with varied exposures or multi-story layouts avoid overheating one area to warm another. Variable-speed blowers and modulating burners or compressors smooth out temperature swings and reduce noise, which often makes a space feel warmer at the same setpoint.

Upgrades to consider, depending on your starting point:

– Duct sealing and balancing to reduce losses and improve room-to-room consistency.

– Hydronic outdoor reset controls for lower supply temperatures on mild days.

– Weatherization measures that stack benefits across seasons, from draft control to quieter rooms.

– Heat pump retrofits or hybrids in regions with moderate electricity prices and improving grids.

– For renters: draft stoppers, smart plug timers for small heaters, and thermal curtains that are removable and landlord-friendly.

Operation habits also matter. Keep interior doors and returns unobstructed, set realistic temperature targets, and avoid using ovens or unvented combustion for space heating. If you rely on portable heaters, dedicate a safe zone with nonflammable surroundings and plug them directly into wall outlets. In hydronic homes, simple accessories like radiator reflectors can nudge more heat into the room instead of the exterior wall; periodic bleeding keeps performance steady. For radiant floors, avoid thick rugs that act like insulation caps over the warmth you want to feel.

Conclusion for homeowners and renters: A comfortable, efficient home emerges from a clear plan—tighten the shell, choose a system that fits the climate and building, and maintain it with regular, simple tasks. Look at the numbers (AFUE, HSPF, COP), but remember the distribution that delivers the heat and the controls that steer it. Whether you live in a compact apartment or a sprawling older house, there is a path to steadier warmth and calmer bills. Take one step this season—seal a leak, change a filter, tune a thermostat—and the next steps get easier, like footprints in fresh snow leading toward a warmer winter.